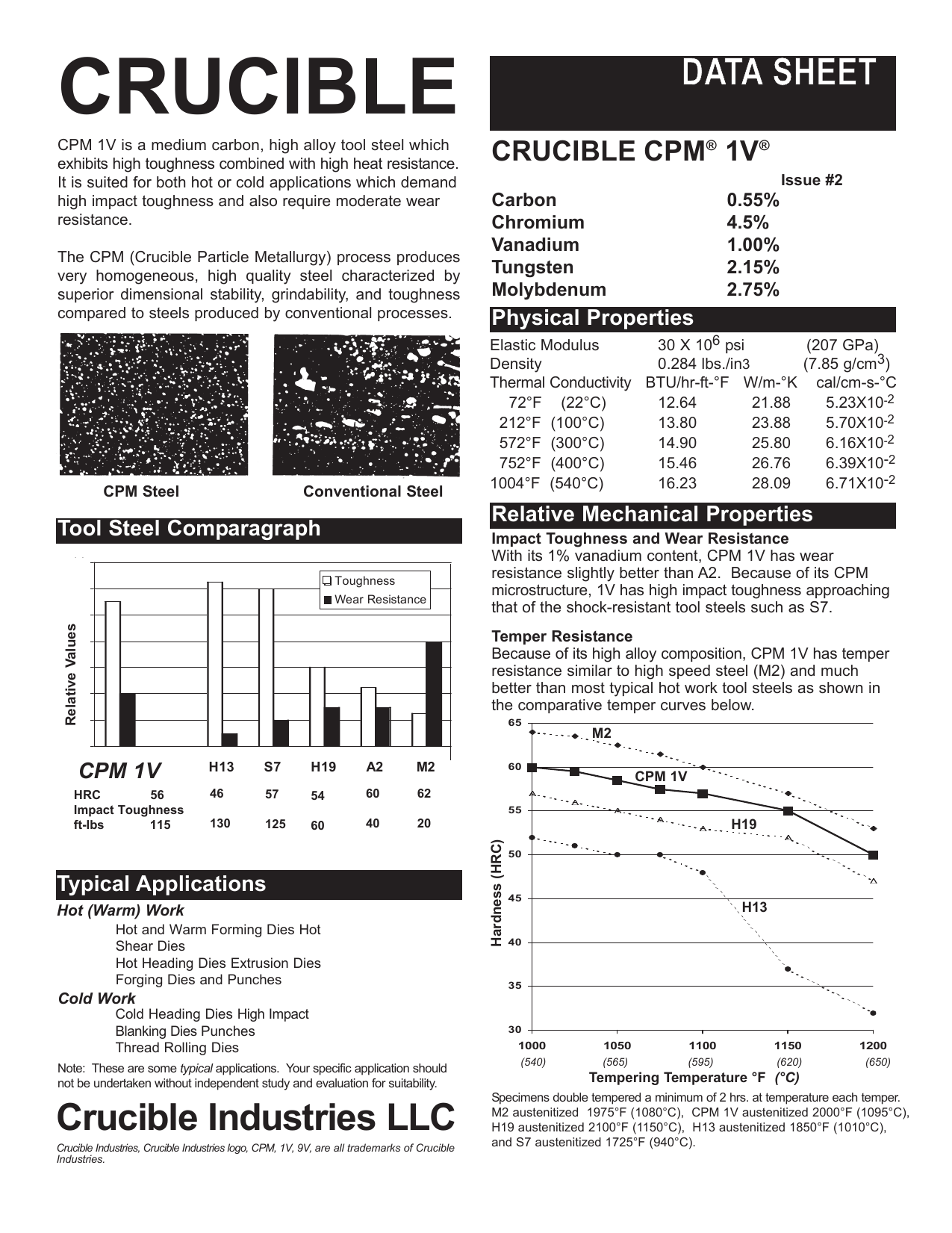

S7 tool steel is an air hardening or oil hardening tool steel that is characterized by its shock resistance excellent toughness high compression strength and medium wear resistance.

S7 tool steel data sheet.

Aisi s7 steel has exceptional impact properties highest hardenability.

Aisi s7 tool steel is a shock resistant air hardening steel.

S7 shock resisting tool steel is an air or oil hardening tool steel that is characterized by very high impact toughness.

Technical specification of astm standards impact resistance tool steel s7 datasheet s7 chemical compositions s7 mechanical properties from steelmaking esr melted blooming hot forging hot rolling heat treatment straightening 100 ultrasonic test cold working or rough turned machining.

S7 can be supplied as steel plate sheet round steel bar steel tube pipe steel stripe steel billet steel ingot steel wire rods.

Air hardening and versatile enough for use in both cold and hot work tooling make s7 suitable for a wide range of applications that require shock resistance size stability and machinability where temperatures of the tool will not exceed 1000 f.

It has maximum shock resistance and high compression strength which gives it good deformation resistance in use while retaining good toughness.

High speed steel to prevent from abrasion.

S7 is easy to machine in the annealed condition and can be readily heat treated.

The combination of strength and high toughness makes it a candidate for a wide variety of tooling applications.

Stainless steel special steel compressor blading turbine blading superalloy supplier.

S7 is a shock resistant air hardening tool steel designed for high impact resistance at relatively high hardness.

The exceptional toughness and shock resistant qualities of this steel makes it a great option for a variety of tooling applications.

S7 tool steel grade shapes sizes and technical information from tool steel service inc.

Technical specification astm a681 2004.

S7 is a shock resisting tool steel with excellent toughness and high strength along with medium wear resistance.

It can be used successfully for both cold and hot work applications.

Steel for ame hardening resulting in high hardness and small strain even with air quenched.

These bars are decarb free for a uniform surface that will consistently accept heat treating.

It is an air hardening material.

It offers toughness to withstand chipping and breaking combined with high attainable hardness and good wear resistance.

Tool die steels inc.

Often made into chisels rivets and punches s7 tool steel can handle repeated impact without fracturing.

Dies for deep drawing.

S 7 tool steel data sheet.

Electroslag forged ring block etc.